In the modern construction and mining industries, having the right equipment can significantly impact efficiency, safety, and costs. One of the most essential tools in excavation and demolition work is the hydraulic breaker. This powerful attachment is commonly used on excavators and skid steers to break rocks, concrete, and other tough materials. With so many variations on the market, choosing the right hydraulic breaker for your specific needs is crucial.

Among the most popular types are side type hydraulic breakers and top type hydraulic breakers. Both serve similar purposes but have distinct structural differences, applications, and performance characteristics. Understanding these differences will help contractors, operators, and procurement managers make informed decisions.

In this comprehensive guide, we will explore what side type and top type hydraulic breakers are, how they differ, and which one might be best suited for your project needs. We'll also include data comparisons, product features, and FAQs to address common concerns in the industry.

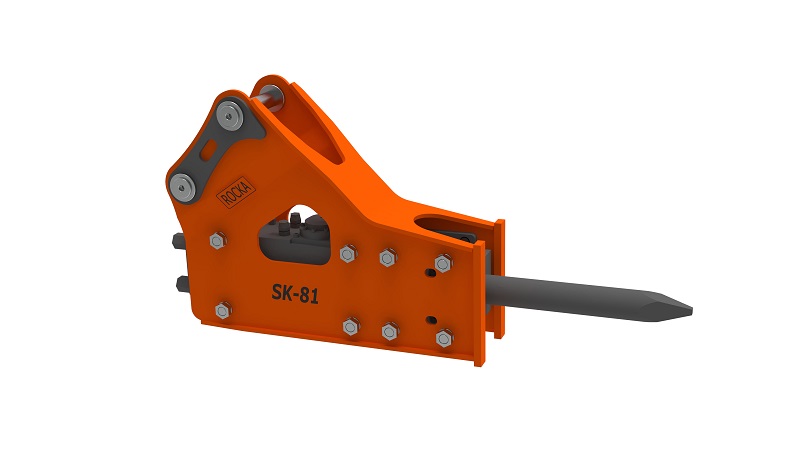

What is Side Type Hydraulic Breaker?

A side type hydraulic breaker, as the name suggests, is a specific configuration where the hydraulic hammer mechanism is mounted laterally—on the side of the bracket structure. This design results in a more compact profile, especially beneficial when working in narrow or confined spaces.

Key Features of Side Type Hydraulic Breaker:

Lateral Mounting: The cylinder and piston are aligned on the side, offering a lower center of gravity.

Compact and Slim Design: Ideal for operations in tight areas or against vertical surfaces.

Less Height, More Width: Compared to top type breakers, side-mounted models are shorter in height but wider in form.

Excellent for Urban Work: Side type models are often favored for demolition jobs in urban environments due to their maneuverability.

Applications:

Concrete demolition in building interiors

Trenching in narrow urban roads

Secondary breaking in mines and quarries

Tunnel construction

The side type hydraulic breaker is often preferred when precision and compactness are more important than sheer impact force.

What is Top Type Hydraulic Breaker?

In contrast, a top type hydraulic breaker features a vertical or top-down mounting system. The hydraulic hammer is mounted directly on the top of the excavator arm, which aligns the impact force directly with the arm's axis. This design provides enhanced energy transfer and greater efficiency in high-power applications.

Key Features of Top Type Hydraulic Breaker:

Vertical Alignment: The piston and cylinder are aligned straight with the excavator boom.

More Powerful Impact: Direct alignment allows for increased efficiency and stronger blows.

Better Weight Distribution: Designed to transfer the force straight down, reducing stress on the excavator arm.

Durable Construction: Often built with heavy-duty materials to withstand larger rocks and longer usage.

Applications:

A top type hydraulic breaker is the go-to choice for contractors working in open areas requiring significant impact force and deep penetration into tough materials.

Difference Between Side Type and Top Type Hydraulic Breaker

To better understand the comparison, let's analyze the key differences between side type and top type hydraulic breakers across various parameters:

| Feature/Aspect | Side Type Hydraulic Breaker | Top Type Hydraulic Breaker |

| Mounting Position | Side-mounted | Top-mounted |

| Design Structure | Compact and wide | Taller and narrow |

| Impact Force | Medium to low impact | High impact power |

| Weight Distribution | Uneven, more stress on bracket | Even, aligned with excavator arm |

| Ideal Applications | Urban demolition, trenching, tunneling | Mining, quarrying, road construction |

| Ease of Maintenance | Easier to access side components | May require more effort due to vertical assembly |

| Durability | Suitable for light to medium tasks | Built for heavy-duty applications |

| Noise Levels | Lower, due to side isolation | Can be higher due to direct impact |

| Cost | Generally cheaper | Typically more expensive due to robust design |

| Excavator Compatibility | Small to medium excavators | Medium to large excavators |

Performance Comparison

According to field reports and user reviews:

Top type hydraulic breakers deliver up to 15% more impact energy compared to side type models.

Side type breakers are approximately 20% more effective in confined area operations due to better maneuverability.

Maintenance costs for side type models are around 10-15% lower, especially in low-impact environments.

Conclusion

Choosing between a side type and top type hydraulic breaker ultimately depends on your specific job requirements. If your work involves urban construction, tight spaces, or light-duty operations, the side type hydraulic breaker offers the flexibility and ease of use you need. On the other hand, if your projects demand maximum impact, deep penetration, and durability, the top type hydraulic breaker is the more powerful and efficient option.

The manufacturing quality, brand reputation, and compatibility with your excavator or backhoe are equally important considerations. Always match the hydraulic breaker model with the workload, frequency of use, and working environment for the best performance and return on investment.

In today's competitive construction and mining sectors, understanding the nuances between different breaker attachments is not just a technical necessity—it's a strategic advantage. Whether you're purchasing new equipment or upgrading your fleet, knowing the difference between side type and top type hydraulic breaker can save time, money, and maintenance headaches.

FAQs

Q1: What is a hydraulic breaker used for?

A hydraulic breaker is a powerful percussion hammer fitted to an excavator for demolishing concrete, rocks, and other hard materials. It is commonly used in construction, demolition, quarrying, and mining.

Q2: Can I use the same hydraulic breaker on different excavators?

It depends on the breaker attachment's compatibility. Most manufacturers provide adapter kits or universal mounting systems, but weight class and hydraulic flow must match the carrier unit.

Q3: Are side type hydraulic breakers more affordable?

Yes, side type hydraulic breakers usually come at a lower price point due to their simpler design and are best for light to medium-duty tasks.

Q4: Which hydraulic breaker is better for mining?

The top type hydraulic breaker is more suitable for mining due to its higher impact energy, direct alignment with the excavator arm, and durable build for heavy-duty applications.

Q5: How often should I maintain my hydraulic breaker?

Regular maintenance includes daily greasing, weekly bolt torque checks, and monthly inspection of the chisel and bushing. Hydraulic hammers used in high-impact environments may need more frequent servicing.

Q6: Is there a difference in noise levels between side and top type breakers?

Yes, side type breakers tend to be quieter, making them more suitable for urban or residential projects.

Q7: Can I retrofit my existing excavator with a top type breaker?

Yes, but ensure your excavator has the appropriate hydraulic flow, pressure, and bracket configuration to support a top type hydraulic breaker.

Q8: What is the average lifespan of a hydraulic breaker?

With proper maintenance, a hydraulic breaker can last between 3,000 to 5,000 working hours, though this varies based on usage conditions and material hardness.

Q9: How do I choose the right chisel for a hydraulic breaker?

Chisel selection depends on the material being broken. Use a pointed chisel for hard rock, a blunt chisel for concrete, and a flat chisel for asphalt or layered materials.