The construction industry is undergoing a transformation, driven by sustainability goals, stricter environmental regulations, and the need to reduce costs. One of the most pressing challenges is dealing with the massive volume of construction and demolition (C&D) waste, particularly concrete and asphalt. Instead of treating these materials as landfill-bound debris, innovative technologies now allow them to be processed and reused in new projects. At the center of this change is the hydraulic breaker—a versatile, powerful tool designed for breaking down tough materials efficiently.

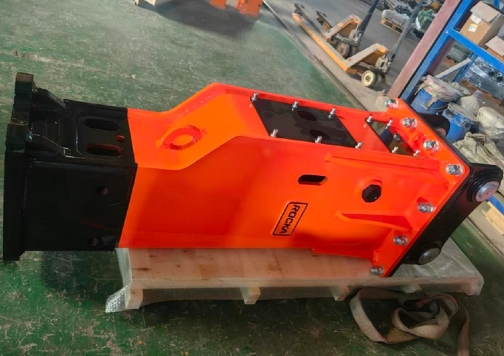

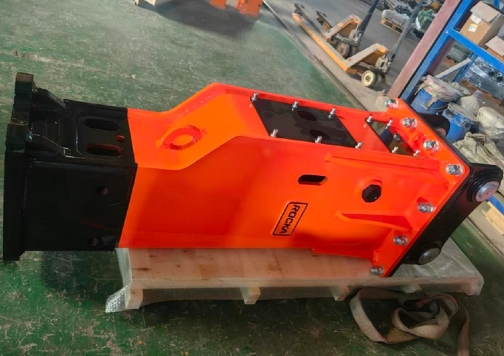

What Is a Hydraulic Breaker?

A hydraulic breaker, also known as a rock breaker or hydraulic hammer, is an attachment for excavators, backhoes, or skid steers. Powered by hydraulic systems, it delivers high-impact blows to fracture hard materials such as rock, reinforced concrete, and asphalt. Unlike traditional manual demolition tools, hydraulic breakers provide precision, power, and efficiency in demanding environments.

In recycling operations, their ability to crush and fragment concrete slabs, asphalt pavements, and other hard materials makes them indispensable.

Why Recycling Concrete and Asphalt Matters

Construction and demolition (C&D) waste is one of the largest waste streams worldwide, with concrete and asphalt making up a significant share. Traditionally, these materials were often discarded in landfills, leading to environmental and economic challenges. Today, however, recycling them has become a cornerstone of sustainable construction practices.

1. Environmental Sustainability

Recycling reduces the need for extracting virgin aggregates, which helps conserve finite natural resources like gravel and sand. It also decreases reliance on landfills, minimizing soil and water pollution while lowering greenhouse gas emissions associated with quarrying and transportation.

2. Economic Savings

Producing recycled aggregates is far more cost-effective than quarrying new materials. In addition, when recycling takes place directly on-site, transportation and disposal costs are significantly reduced. This makes recycling both a practical and financially attractive choice for contractors.

3. Regulatory Compliance

Governments worldwide are enforcing stricter environmental standards. Many now require recycling of C&D waste and limit what can be sent to landfills, making sustainable practices not just optional but mandatory.

4. Circular Economy Contribution

Instead of being discarded, waste concrete and asphalt are transformed into valuable raw materials, closing the loop in construction. This supports a circular economy, where resources are reused, and waste is minimized.

Hydraulic breakers play a crucial role here, breaking down large slabs into manageable sizes that can be crushed, screened, and repurposed efficiently.

How Hydraulic Breakers Support Recycling

Hydraulic breakers play a central role in transforming what was once considered solid waste into valuable, reusable resources. Their ability to deliver powerful, controlled impact makes them indispensable in concrete and asphalt recycling operations. Here’s a closer look at how they support this process:

1. Breaking Concrete Structures

Hydraulic breakers are widely used to demolish old buildings, parking decks, and bridge structures. Thanks to their tremendous impact energy, they can penetrate even heavily reinforced concrete, breaking it into smaller fragments. These smaller pieces are easier to handle and transport, and more importantly, they are suitable for further crushing and screening. Without this initial step, recycling reinforced structures would be far less efficient.

2. Asphalt Pavement Removal

In road rehabilitation or resurfacing projects, hydraulic breakers are used to quickly break up worn or damaged asphalt pavements. The broken asphalt is then collected and sent to specialized plants, where it is reheated and mixed with fresh binder to produce new asphalt. This process reduces the demand for virgin bitumen and aggregates, making road construction more sustainable and cost-effective.

3. On-Site Processing

One of the greatest advantages of hydraulic breakers is their ability to reduce material size directly at the demolition site. Instead of hauling oversized slabs to a distant recycling facility, contractors can break them down on-site. This significantly reduces transportation costs, lowers emissions from trucks, and allows immediate reuse of the processed material as backfill or road sub-base.

4. Preparing Material for Crushers

Recycling facilities often require feedstock to be within a certain size range for efficient processing. Hydraulic breakers provide the first stage of size reduction, ensuring that crushers and grinders operate more efficiently and suffer less wear. By pre-conditioning the material, breakers extend the service life of downstream equipment and optimize overall throughput.

5. Reducing Dust and Noise Pollution

Modern hydraulic breakers are designed with advanced noise-reduction and vibration-damping features. This not only protects operators from excessive noise and vibration exposure but also makes the equipment more suitable for urban environments where noise and dust regulations are strict. With additional dust-suppression measures, breakers can operate responsibly while maintaining high productivity.

In short, hydraulic breakers bridge the gap between demolition and recycling, making the conversion of concrete and asphalt waste into reusable resources faster, safer, and more efficient.

Advantages of Using Hydraulic Breakers in Recycling

Efficiency and Speed

Hydraulic breakers deliver thousands of blows per minute, accelerating demolition and recycling operations.

Versatility

They can be mounted on various carriers and used in construction, mining, quarrying, and recycling, making them a multipurpose investment.

Precision Work

Breakers allow for targeted demolition without damaging surrounding structures, ideal for urban recycling projects.

Cost Savings

By breaking materials on-site, companies save on hauling, disposal fees, and virgin material costs.

Extended Equipment Life

Crushers and grinders experience less wear when fed pre-broken material from hydraulic breakers.

Case Applications in Recycling

Case 1: Urban Building Demolition

In a city center redevelopment project, hydraulic breakers were used to dismantle reinforced concrete buildings. The broken material was immediately processed and reused as aggregate for new construction, reducing both waste and costs.

Case 2: Highway Rehabilitation

During highway resurfacing, breakers removed old asphalt layers efficiently. The reclaimed asphalt pavement (RAP) was recycled into new asphalt mixes, cutting project expenses by nearly 20%.

Case 3: Industrial Plant Renovation

Hydraulic breakers helped dismantle concrete foundations in an abandoned factory. The recycled concrete was crushed and used as base material for a new logistics facility on the same site.

These examples highlight how hydraulic breakers enable sustainable practices while improving project economics.

Best Practices for Using Hydraulic Breakers in Recycling

Proper Equipment Selection

Match the breaker size and energy class to the carrier and material hardness. Oversized or undersized breakers reduce efficiency.

Regular Maintenance

Keep the breaker’s chisel, bushings, and seals in good condition to maximize performance and longevity.

Operator Training

Skilled operators can optimize impact force, minimize unnecessary wear, and enhance safety during recycling operations.

Integration with Other Equipment

Use breakers alongside crushers, screeners, and conveyors to build a complete recycling line.

Environmental Considerations

Employ dust suppression measures and low-noise models to meet environmental regulations and protect workers’ health.

Conclusion

The construction industry’s shift toward sustainability has created a growing demand for efficient recycling solutions. Hydraulic breakers stand out as a powerful, versatile tool that transforms concrete and asphalt waste into reusable resources. By enabling faster demolition, efficient material processing, and reduced costs, they play a critical role in building a circular construction economy.

For businesses seeking reliable hydraulic breakers designed for demanding recycling applications, Yantai Rocka Machinery Co., Ltd. offers advanced solutions tailored to modern needs. Their equipment is engineered for durability, efficiency, and environmental responsibility. To learn more about their products or explore how hydraulic breakers can enhance your recycling operations, consider reaching out to their team for expert guidance.