Introduction

In the realm of modern construction and agriculture, the Hydraulic Post Driver has emerged as an indispensable tool. Its ability to efficiently drive posts into the ground has revolutionized tasks that once required significant manual labor and time. As infrastructure projects and farming operations expand globally, mastering the operation of hydraulic post drivers becomes increasingly vital. This comprehensive guide delves into the essential steps required to operate these machines proficiently, ensuring safety, efficiency, and longevity of the equipment.

Understanding the intricacies of hydraulic systems and their applications is crucial for professionals aiming to enhance their operational skills. Hydraulic post drivers leverage the principles of fluid mechanics to deliver powerful force, making them superior to traditional methods. However, their effectiveness is contingent upon proper handling and maintenance. This guide not only elucidates the operational steps but also integrates theoretical knowledge, practical advice, and expert insights to provide a holistic understanding of hydraulic post driver operation.

Step 1: Comprehending Hydraulic System Fundamentals

Before operating a hydraulic post driver, it's imperative to grasp the basic principles of hydraulics. At its core, hydraulics involves the use of pressurized fluids to generate, control, and transmit power. This technology harnesses the incompressibility of liquids to transmit force efficiently through confined spaces. The hydraulic post driver utilizes this principle by converting hydraulic energy into mechanical force, driving posts into the ground with precision and power.

The key components of a hydraulic system include the hydraulic fluid, pump, cylinder (actuator), valves, and hoses. The hydraulic fluid, often oil, transmits power throughout the system. The pump generates the necessary flow and pressure, while the cylinder converts fluid power into linear motion. Valves control the direction and flow rate of the fluid, and hoses transport the fluid between components.

Understanding these components and their functions is crucial. For instance, knowing how the hydraulic pump affects pressure and flow can help in diagnosing performance issues. Familiarity with the system's design enhances the operator's ability to use the equipment effectively, ensuring optimal performance and safety.

The Importance of Hydraulic Fluid Quality

Hydraulic fluid is more than just a medium for transmitting power; it also lubricates components, reduces wear, and helps dissipate heat. Selecting the appropriate fluid with the correct viscosity and additives is essential. Contaminated or degraded fluid can lead to inefficiencies, increased wear, and even system failure. Regularly checking and replacing hydraulic fluid according to the manufacturer's recommendations preserves the system's integrity.

Step 2: Preparing for Safe Operation

Safety preparation is a critical step in operating a hydraulic post driver. Before commencing any work, operators must conduct a thorough inspection of the equipment and the work site. This includes checking for damaged or worn components, ensuring all fittings and hoses are secure, and verifying that the hydraulic fluid levels are adequate.

Personal Protective Equipment (PPE) is mandatory. Operators should wear safety glasses, gloves, steel-toed boots, and hearing protection. Loose clothing or accessories that could become entangled in the machinery must be avoided. Additionally, understanding the environmental conditions, such as the type of soil and weather, can influence the operation and should be evaluated beforehand.

Site Assessment and Hazard Identification

A comprehensive site assessment helps identify potential hazards. Operators must look for underground utilities, overhead obstructions, and uneven terrain. Marking the locations of electrical lines, gas pipes, and water mains prevents accidental damage and ensures safety. It's also important to assess soil conditions, as rocky or hard-packed soil may require adjustments to operating techniques.

Step 3: Efficient Operation Techniques

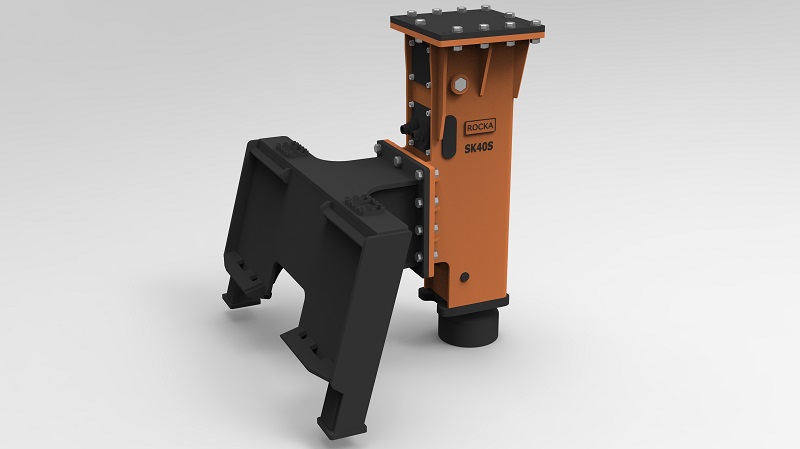

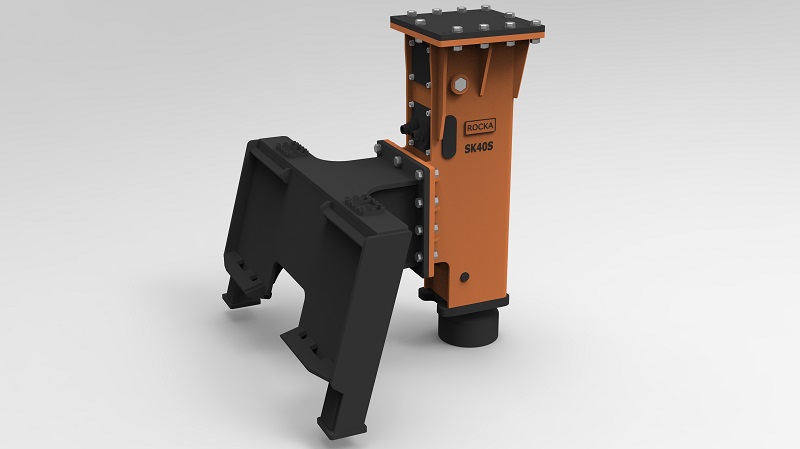

Operating the hydraulic post driver efficiently requires a combination of skill, knowledge, and adherence to best practices. Starting with the correct setup, the post driver should be securely attached to the carrier machine, whether it's a tractor, skid steer, or excavator. Ensuring compatibility between the hydraulic flow rate and pressure of the carrier and the post driver is crucial for optimal performance.

When positioning the post, it should be aligned accurately with the desired location. The post driver must be lowered onto the top of the post gently to avoid damage. Applying steady and consistent force allows the post to penetrate the ground smoothly. Operators should monitor the pressure gauges to ensure they stay within recommended parameters, avoiding excessive force that could harm the equipment or the post.

Adjusting to Soil Conditions

Different soil types require adjustments in operation. In soft soils, posts may drive easily but require careful alignment to prevent tilting. In contrast, hard or rocky soils demand more force and potentially the use of pilot holes. Understanding how to adapt the driving technique based on soil conditions enhances efficiency and reduces wear on the equipment.

Minimizing Pressure Loss and Heat Generation

Pressure loss in hydraulic systems can lead to inefficiencies and excessive heat generation. Using hoses and fittings of appropriate size minimizes friction losses. Keeping the hydraulic fluid clean and at the correct viscosity also helps maintain system efficiency. Monitoring the temperature of the hydraulic fluid during operation prevents overheating, which can degrade the fluid and damage components.

Step 4: Routine Maintenance and Troubleshooting

Regular maintenance is essential for the longevity and reliability of the hydraulic post driver. This includes daily inspections before and after use, focusing on components such as hoses, connections, and seals for signs of wear or leaks. Keeping a maintenance log helps track service intervals and component replacements.

Troubleshooting common issues involves understanding the symptoms and potential causes. For instance, reduced driving power may result from low hydraulic fluid levels, clogged filters, or worn seals. Addressing these issues promptly prevents further damage and downtime. Consulting the manufacturer's manual provides guidance on specific maintenance procedures and troubleshooting steps.

Hydraulic Fluid Contamination Control

Contaminated hydraulic fluid is a leading cause of system failures. Implementing strict contamination control measures, such as using clean containers for fluid storage and employing filtration systems, protects the hydraulic components. Regular fluid analysis can detect contaminants early, allowing for corrective actions before significant damage occurs.

Seal and Hose Inspection

Seals and hoses are critical for maintaining system pressure and preventing leaks. Regular inspection for cracks, abrasions, or bulges is necessary. Replacing worn or damaged hoses and seals ensures the system operates at peak efficiency and reduces the risk of sudden failures during operation.

Step 5: Advanced Techniques and Best Practices

Mastering the hydraulic post driver involves not only following basic operational steps but also implementing advanced techniques that enhance productivity and extend equipment life. Operators should stay informed about the latest technological advancements and training opportunities.

Utilizing data from the hydraulic system can inform decisions about maintenance schedules and operational adjustments. For example, integrating sensors and monitoring equipment can provide real-time feedback on system performance. This proactive approach allows for predictive maintenance, reducing unexpected downtime.

Training and Skill Development

Continuous training ensures operators are adept at using the equipment efficiently and safely. Manufacturers often provide training resources, and professional certifications can enhance an operator's expertise. Sharing knowledge within a team promotes best practices and keeps everyone informed about new techniques and safety protocols.

Equipment Upgrades and Customization

Advancements in hydraulic technology offer opportunities to upgrade equipment for better performance. This might include installing more efficient pumps, utilizing environmentally friendly hydraulic fluids, or integrating smart control systems. Customizing the post driver to suit specific applications can improve productivity and adapt the equipment to unique operational needs.

Conclusion

Mastering the operation of a hydraulic post driver is a multifaceted endeavor that combines technical knowledge, practical skills, and a commitment to safety and maintenance. By understanding hydraulic fundamentals, preparing thoroughly, employing efficient operation techniques, maintaining the equipment diligently, and embracing advanced practices, operators can significantly enhance their productivity and the lifespan of their machinery.

The Hydraulic Post Driver stands as a testament to the power of hydraulic technology in modern industry. As operators continue to refine their skills and adopt innovative approaches, the potential for increased efficiency and success in their projects grows exponentially. Investing time and effort into mastering these essential steps yields dividends in performance, safety, and operational excellence.

Frequently Asked Questions (FAQs)

1. What Factors Affect the Efficiency of a Hydraulic Post Driver?

Several factors influence the efficiency of a hydraulic post driver, including hydraulic fluid quality, system pressure, flow rate, and the condition of components such as pumps and valves. Contaminated or degraded hydraulic fluid can reduce efficiency by causing increased friction and wear. Proper maintenance of the hydraulic system, including regular fluid changes and filter replacements, ensures optimal performance. Additionally, using hoses and fittings that minimize pressure loss helps maintain the desired force output.

2. How Does Soil Condition Impact Post Driving Operations?

Soil conditions significantly affect the operation of a hydraulic post driver. Soft soils allow for easier driving but may require attention to alignment to prevent posts from tilting. Hard or rocky soils present more resistance, necessitating greater force and possibly the use of pilot holes to facilitate driving. Adjusting operating techniques based on soil type enhances efficiency and reduces strain on the equipment.

3. What Safety Measures Should Be Taken When Operating a Hydraulic Post Driver?

Safety measures include conducting thorough equipment inspections, wearing appropriate PPE such as safety glasses, gloves, and hearing protection, and performing a site assessment to identify potential hazards like underground utilities or uneven terrain. Operators should also ensure that all hydraulic connections are secure and that the system is functioning within the manufacturer's recommended parameters to prevent accidents.

4. Why Is Regular Maintenance Important for Hydraulic Systems?

Regular maintenance is crucial for preventing system failures, extending equipment life, and ensuring efficient operation. Maintenance tasks include inspecting hoses and seals for leaks or wear, replacing hydraulic fluid and filters, and monitoring system pressure and temperature. Proactive maintenance reduces downtime and repair costs by addressing issues before they escalate.

5. How Can Operators Improve Their Skills in Using Hydraulic Post Drivers?

Operators can enhance their skills by participating in training programs offered by manufacturers or industry organizations. Staying updated on the latest technological advancements, learning from experienced colleagues, and practicing advanced techniques contribute to skill development. Understanding both the theoretical and practical aspects of hydraulic systems leads to more effective and efficient operation.

6. What Role Do Advanced Technologies Play in Hydraulic Post Driver Operation?

Advanced technologies such as sensors, smart controls, and improved materials enhance the performance and reliability of hydraulic post drivers. Sensors can provide real-time data on system performance, enabling predictive maintenance and optimization. Smart controls allow for more precise operation, and advanced materials extend component life and reduce maintenance needs.

7. How Does Understanding Hydraulic Fundamentals Benefit Operators?

Understanding hydraulic fundamentals equips operators with the knowledge to troubleshoot issues, optimize performance, and operate the equipment safely. Recognizing how components like pumps, valves, and cylinders interact within the system allows operators to make informed decisions during operation and maintenance. This foundational knowledge is essential for maximizing the effectiveness of the hydraulic post driver.